PROCESS DEVELOPMENT

Developing an API is more than just synthesizing a molecule. It is about designing a process that is safe, scalable, and commercially viable. At Lupin Manufacturing Solutions, our Process Development & Optimization services are designed to seamlessly transition your lab-scale chemistry into robust, industrial processes ready for kilo-scale, pilot, and full commercial production.ss By applying Quality by Design (QbD), Design of Experiments (DoE), and Process Analytical Technology (PAT) principles, we deliver processes that are not only efficient but also regulatory-compliant and cost-competitive.

Why Process Development Matters

A poorly designed process can lead to:

- Low yields and high cost of goods

- Uncontrolled impurities impacting safety and compliance

- Scalability challenges leading to delays or failures at pilot scale

- Regulatory setbacks due to lack of robust control strategies

Our approach ensures your process is fit for purpose from the very beginning, de-risking your clinical and commercial supply chains.

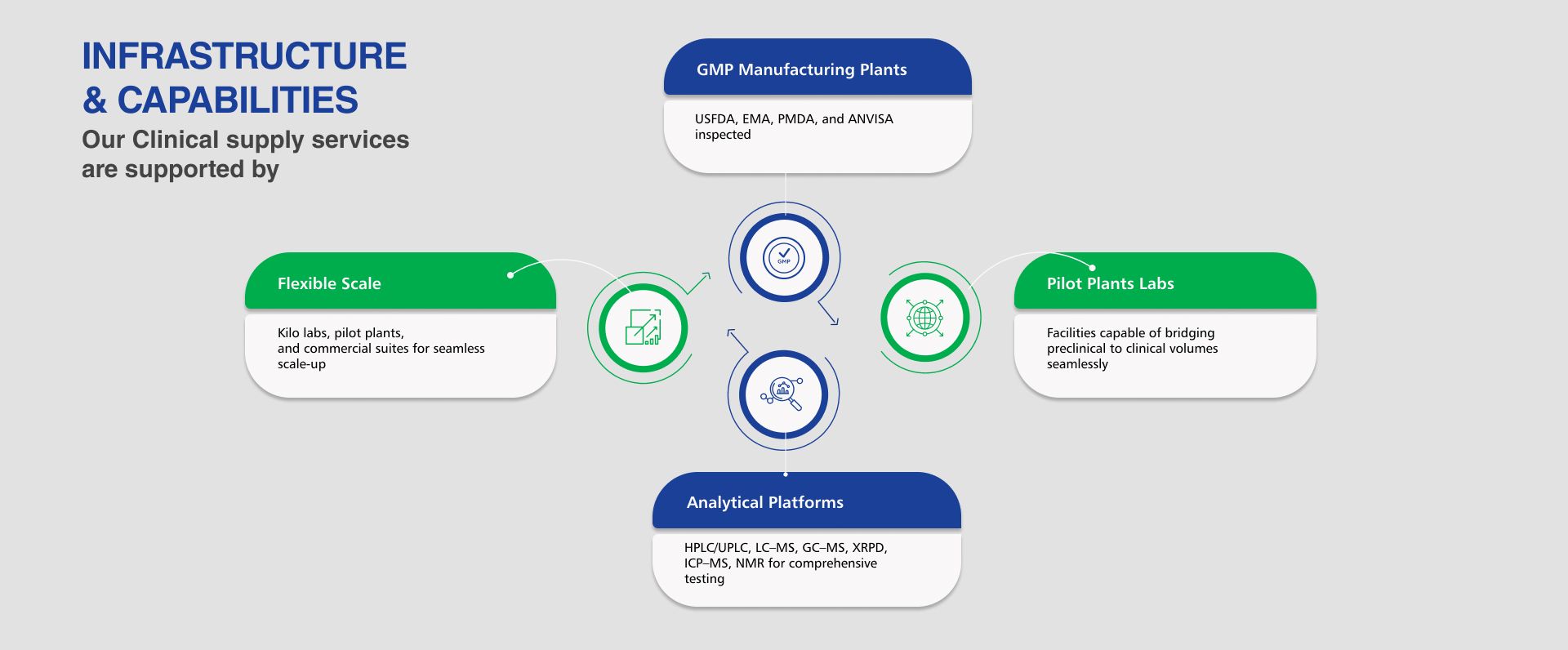

TECHNOLOGY & INFRASTRUCTURE

- Advanced Labs State-of-the-art R&D centers with kilo-labs and pilot plants

- PAT Tools In-line FTIR, NIR, and Raman spectroscopy for real-time monitoring

- Digital Data Systems Integrated ELN and LIMS platforms for data integrity

- Cross-Functional Teams Chemists, chemical engineers, analysts, and safety specialists working under one roof

WHY LMS ?

- Deep chemistry expertise Cryogenic, enzymatic, organometallic, and flow chemistry

- Proven regulatory track record 100+ global inspections and approvals

- Integration with manufacturing Same network supports clinical and commercial supply

- Speed to scale Rapid cycle development with decision gates for faster project timelines

- Sustainability embedded Greener solvents, lower waste, and reduced energy usage